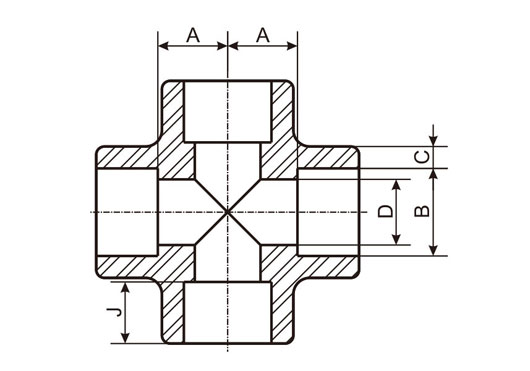

Socket Welding Cross

Pambuka produk

Fitting pipa welding soket digawe kanthi nglebokake pipa baja tahan karat menyang soket pipa fitting lan nyurung menyang langkah lokasi soket, lan nindakake welding argon circular shielded ing sadawane kontak antarane ujung soket fitting pipa lan njaba. tembok saka pipa.Welding kabel ora dibutuhake (tinimbang soket mburi fitting pipe), kang belongs kanggo "sambungan free sambungan" mode sambungan pipe.

Salib soket kasusun saka soket, soket, bagean mlengkung, soket, lan liya-liyane, sing ditondoi yen ana soket ing soket, lan soket lan soket masing-masing ana ing loro ujung mlengkung. bagean.Ing sistem pipa, salib soket minangka fitting sing ngganti arah pipa.

Tekstur Bahan

Bahan soket welding cross kalebu wesi tuang, baja tahan karat, baja paduan, besi tuang, baja karbon, logam nonferrous lan plastik.

Standar manufaktur utama umume kalebu GB / T14383, ASME B16.11 lan BS3799.

Lingkup Aplikasi

Kopling soket bisa digunakake kanggo pipa kanthi diameter sing beda-beda, kalebu siji, telung arah, papat arah, lan liya-liyane, uga meter banyu lan katup.Amarga nggunakake struktur soket, biaya sambungan pipa dikurangi, lan instalasi, panggunaan lan pangopènan trep banget.Ing wektu sing padha, sambungan pipa duwe kapasitas bukti bocor sing dhuwur banget, sing duwe prospek pasar sing apik.

Ukuran Range

DN6-DN100

Rating tekanan

3000 lb, 6000 lb, 9000 lb

| Kelas Tekanan Las Soket | Jadwal Pipa | ||||

| Kelas 3000 | S80/XH | ||||

| Kelas 6000 | S160 | ||||

| Kelas 9000 | XXH |

Referensi Data

| Spesifikasi Socket Weld Elbow: | |||||

| Ukuran | 1/8″~4″ (DN6~DN100) | ||||

| kelas | 3000 LBS, 6000 LBS, 9000 LBS | ||||

| Jinis | Las soket | ||||

| Perawatan lumahing | Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Soldering | ||||

| Materi | Baja tahan karat, Baja Paduan, Dupleks, Paduan Nikel, Baja Suhu Rendah, Baja Karbon, Nikel Cupro | ||||

| Proses produksi | Cutting, perawatan panas, Forging, Machining | ||||

| Standar Manufaktur | ASME 16.11, GB/T14383-2018, BS-3799 | ||||

| DN | Nom. Ukuran Pipa | Pusat menyang Ngisor Socket-A | Soket Bore Dia.B | Bore Dia. Saka Fitting D | |||||||

| 90° Siku Tees, Salib | 45° Siku | ||||||||||

| Penetapan Kelas | Penetapan Kelas | Penetapan Kelas | |||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | |||

| 6 | 1/8" | 11 | 11 | --- | 8 | 8 | --- | 10.8 | 6.9 | 4 | --- |

| 8 | 1/4" | 11 | 13.5 | --- | 8 | 8 | --- | 14.2 | 9.3 | 6.4 | --- |

| 10 | 3/8" | 13.5 | 15.5 | --- | 8 | 11 | --- | 17.6 | 12.6 | 9.2 | --- |

| 15 | 1/2" | 15.5 | 19 | 25.5 | 11 | 12.5 | 15.5 | 21.8 | 15.8 | 11.8 | 6.4 |

| 20 | 3/4" | 19 | 22.5 | 28.5 | 13 | 14 | 19 | 27.2 | 21 | 15.6 | 11.1 |

| 25 | 1" | 22.5 | 27 | 32 | 14 | 17.5 | 20.5 | 33.9 | 26.7 | 20.7 | 15.2 |

| 32 | 1-1/4" | 27 | 32 | 35 | 17.5 | 20.5 | 22.5 | 42.7 | 35.1 | 29.5 | 22.8 |

| 40 | 1-1/2" | 32 | 38 | 38 | 20.5 | 25.5 | 25.5 | 48.8 | 40.9 | 34 | 28 |

| 50 | 2" | 38 | 41 | 54 | 25.5 | 28.5 | 28.5 | 61.2 | 52.5 | 42.9 | 38.2 |

| 65 | 2-1/2" | 41 | --- | --- | 28.5 | --- | --- | 73.9 | 62.7 | --- | --- |

| 80 | 3" | 57 | --- | --- | 32 | --- | --- | 89.8 | 78 | --- | --- |

| 100 | 4" | 66.5 | --- | --- | 41 | --- | --- | 115.2 | 102.3 | --- | --- |

| Ketebalan Dinding Soket (2) C | Ketebalan Dinding Badan G | Ambane Soket Min.J | |||||||||

| Penetapan Kelas | Penetapan Kelas | ||||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | ||||||

| Ave. | Min. | Ave. | Min. | Ave. | Min. | Min. | Min. | Min. | |||

| 3.18 | 3.18 | 3.96 | 3.43 | --- | --- | 2.41 | 3.15 | --- | 9.5 | ||

| 3.78 | 3.3 | 4.6 | 4.01 | --- | --- | 3.02 | 3.68 | --- | 9.5 | ||

| 4.01 | 3.5 | 5.03 | 4.37 | --- | --- | 3.2 | 4.01 | --- | 9.5 | ||

| 4.67 | 4.09 | 5.97 | 5.18 | 9.35 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 | ||

| 4.9 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 | ||

| 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 | ||

| 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.7 | 12.5 | ||

| 6.35 | 5.54 | 8.92 | 7.8 | 12.7 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 | ||

| 6.93 | 6.04 | 10.92 | 9.5 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16 | ||

| 8.76 | 7.67 | --- | --- | --- | --- | 7.01 | --- | --- | 16 | ||

| 9.52 | 8.3 | --- | --- | --- | --- | 7.62 | --- | --- | 16 | ||

| 10.69 | 9.35 | --- | --- | --- | --- | 8.56 | --- | --- | 16 | ||

1. Tas nyusut-> 2. Kothak cilik-> 3. Karton-> 4. Kasus Kayu Lapis sing Kuat

Salah sawijining panyimpenan kita

Loading

Packing & Pengiriman

1. Pabrik profesional.

2. pesenan Trial ditrima.

3. Layanan logistik sing fleksibel lan trep.

4. Rega sing kompetitif.

5.100% tes, njamin sifat mekanik

6. Tes profesional.

1. Kita bisa njamin materi sing paling apik miturut kutipan sing gegandhengan.

2.Tes dileksanakake ing saben pas sadurunge pangiriman.

3. Kabeh paket adaptasi kanggo kiriman.

4. Komposisi kimia bahan cocog karo standar internasional lan standar lingkungan.

A) Kepiye carane bisa entuk rincian liyane babagan produk sampeyan?

Sampeyan bisa ngirim email menyang alamat email kita.Kita bakal nyedhiyakake katalog lan gambar produk kanggo referensi sampeyan. Kita uga bisa nyuplai fitting pipa, bolt lan nut, gasket dll. Kita ngarahake dadi panyedhiya solusi sistem pipa.

B) Kepiye carane njaluk sawetara conto?

Yen sampeyan butuh, kita bakal menehi conto gratis, nanging pelanggan anyar kudu mbayar biaya ekspres.

C) Apa sampeyan nyedhiyakake bagean khusus?

Ya, sampeyan bisa menehi kita gambar lan kita bakal nggawe sesuai.

D) Negara ngendi sampeyan wis nyedhiyakake produk sampeyan?

Kita wis nyedhiyakake kanggo Thailand, China Taiwan, Vietnam, India, Afrika Kidul, Sudan, Peru, Brazil, Trinidad lan Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, Prancis, Spanyol, Jerman, Belgia, Ukraina etc. (Angka kene mung kalebu pelanggan kita ing paling anyar 5 taun.).

E) Aku ora bisa ndeleng barang utawa ndemek barang, kepiye carane ngatasi risiko?

Sistem manajemen mutu kita tundhuk karo syarat ISO 9001:2015 sing diverifikasi dening DNV.Kita pancen pantes dipercaya.Kita bisa nampa pesenan nyoba kanggo nambah kapercayan bebarengan.

Kategori produk

-

Telpon

-

E-mail

-

Whatsapp

-

Ndhuwur